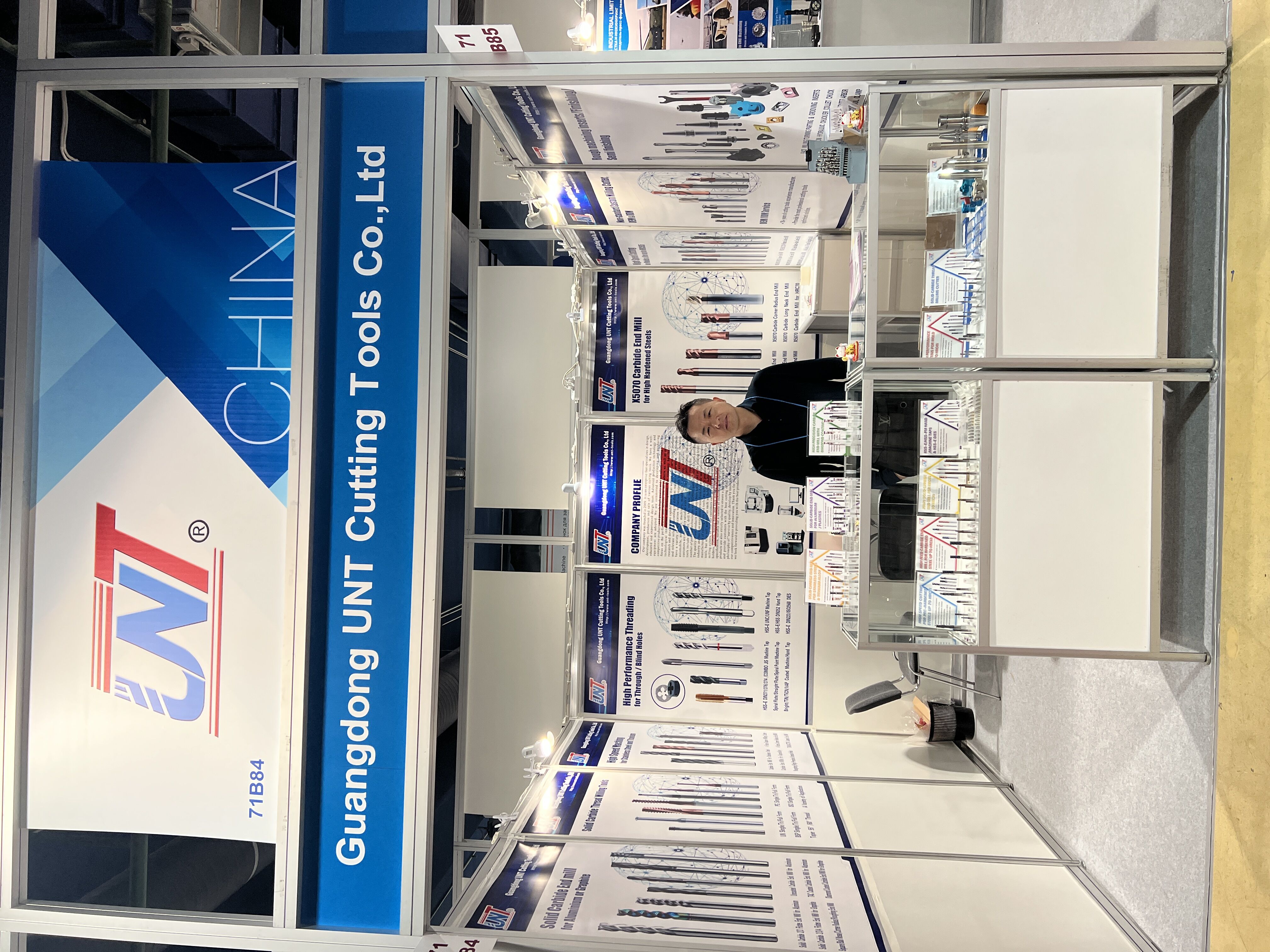

UNT Precision Cutting Tools, a renowned name in the cutting – tool manufacturing industry, is proud to participate in the 2023 Mrtalloobrabotka Moscow. You can explore our comprehensive product range on our official website here.

Product Showcase

UNT presents a diverse and high – quality collection of cutting tools at the exhibition, tailored to meet the needs of various industries.

- Medical – Oriented Tools: Our expertise extends to the medical field with dental bone cutting tools, medical device cutting tools, and other specialized tools for the medical industry. Given the complex nature of medical materials like zirconium alloy, cobalt – chrome alloy, and titanium alloy, our milling tools are engineered to perfection. Manufactured from prime – grade carbide and featuring a special surface treatment by Balzers, they offer top – notch quality and a remarkable return on investment. These tools are vital for producing intricate and accurate medical devices, ensuring the highest standards of patient care.

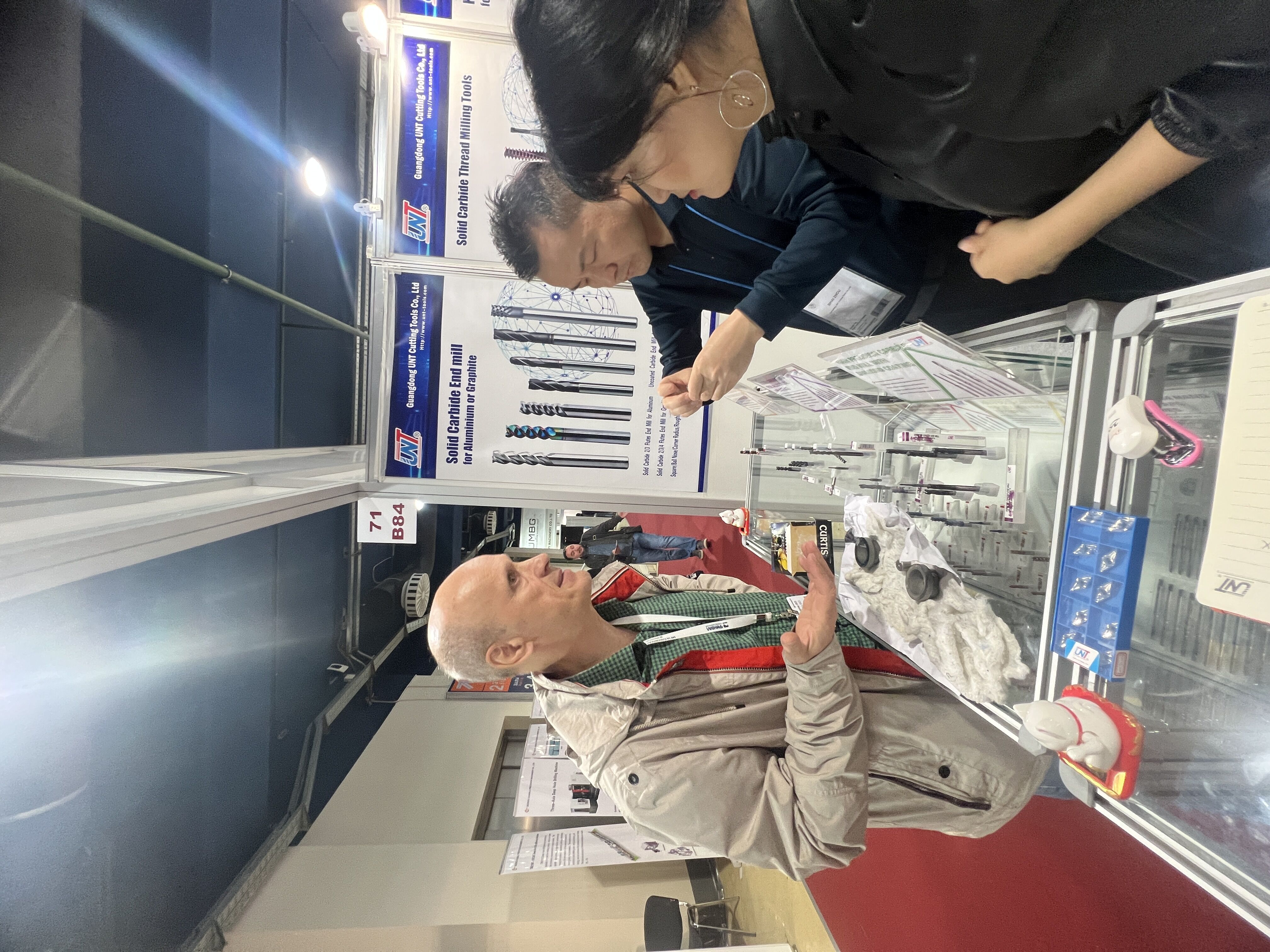

- General – Use Cutting Tools: Our product lineup also includes an array of general – purpose cutting tools. Carbide reamers, carbide taps, and carbide drills are among our signature products. Their outstanding performance is a result of the high – quality carbide used, which provides excellent wear resistance. For different machining needs, we offer a variety of end mills. For instance, single – flute end mills are designed for acrylic, PVC, and MDF materials, while diamond – coated end mills are perfect for non – ferrous materials. The multi – purpose HRC56 solid carbide square 2 – flute end mills are highly versatile and can be used in numerous machining applications.

Manufacturing Excellence

Since 2004, UNT has been committed to excellence in manufacturing. Our 8,000 – square – meter industrial park is equipped with advanced machinery. We have 25 sets of Australian ANCA CNC grinding machines, which are essential for achieving the high – precision manufacturing required for our cutting tools. The German ZOLLER testing equipment ensures strict quality control, guaranteeing that each tool leaving our factory meets the highest quality benchmarks. Our adoption of Swiss OERLIKON new coating technology further enhances the performance and durability of our tools. With a team of 50 professional technicians, we have the know – how to innovate and produce cutting – edge tools that keep pace with the evolving industry demands.

Broad Industry Applications

UNT’s precision cutting tools have a wide range of applications across multiple industries. In the aerospace industry, they play a crucial role in machining high – strength alloys used in aircraft components. For the 3C industry, our miniature specialty cutting tools are used to manufacture electronic devices with utmost precision. In the automotive industry, our tools are employed for machining engine parts and other automotive components with high accuracy. They are also used in nuclear power, heavy machinery, and the molding & die industry. Additionally, in the advertising engraving sector, our tools enable the creation of intricate and detailed designs.

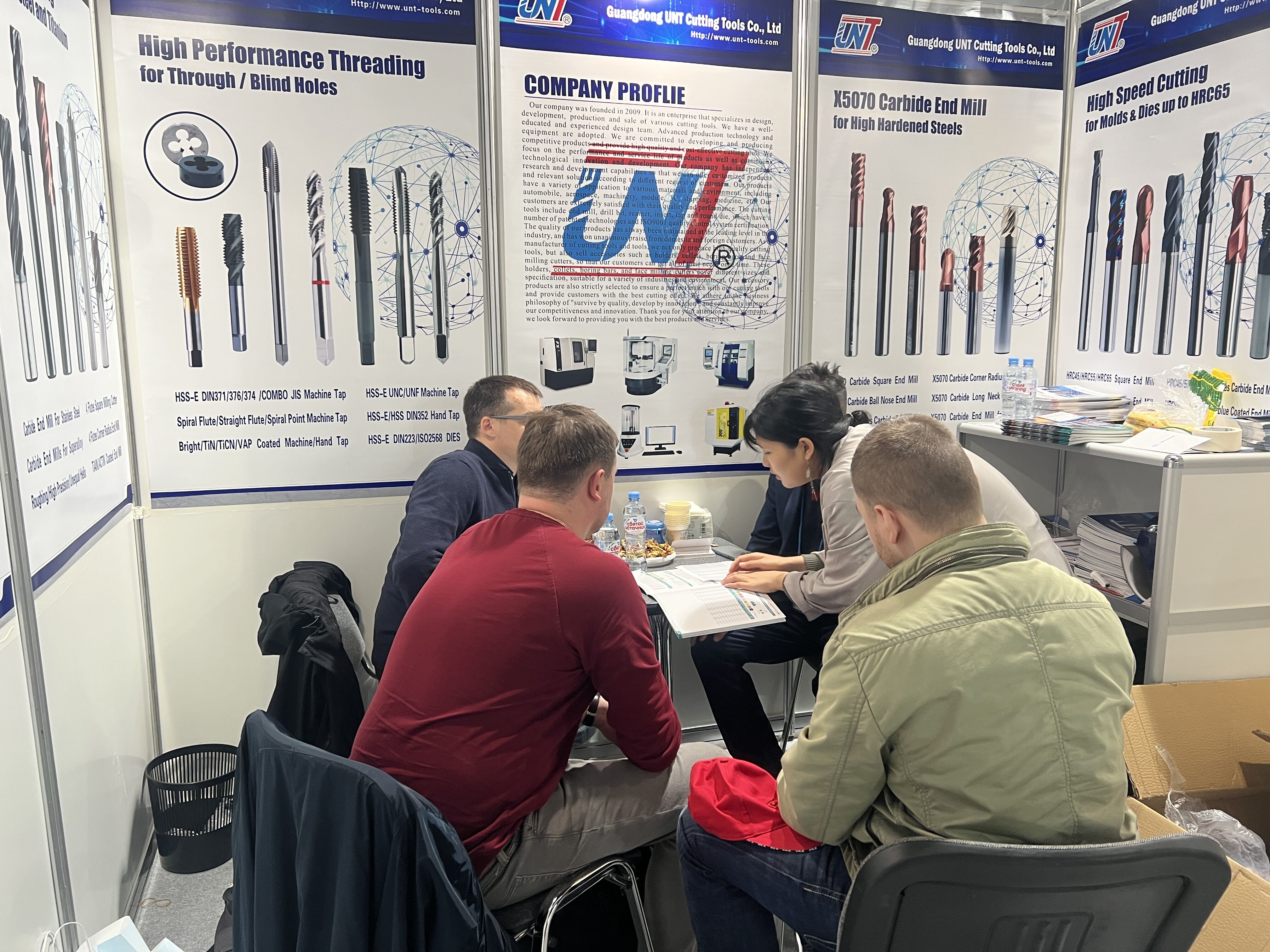

Customer – centric Services

At UNT, we prioritize our customers. We maintain a vast inventory of over 500,000 miniature specialty cutting tools, enabling same – day shipping. This ensures that our customers can minimize production downtime and keep their operations running smoothly. We also offer comprehensive technical services related to mechanical processing. Whether it’s helping customers choose the right tools for their specific applications or providing after – sales support, we are dedicated to building long – term partnerships with our clients. We welcome OEM and ODM projects and work closely with customers to develop customized solutions that meet their unique requirements.

Post time: May-25-2023