In the dynamic landscape of the cutting tools industry, Guangdong UNT Precision Cutting Tools Co., Ltd. has emerged as a trailblazer, consistently delivering top – notch products that meet the diverse needs of various industries.

Established in 2009, this comprehensive high – tech enterprise, with its headquarters in the international manufacturing hub of Dongguan, Guangdong, and a branch in Chengdu, Sichuan, has been making waves since its inception. Spanning over 10,000 square meters, the company is equipped with state – of – the – art facilities, including over 20 imported cylindrical grinders, over 70 imported five – axis grinders, and more than 40 sets of imported precision inspection equipment. With a workforce of over 100 employees, UNT has the capacity to produce over 20,000 milling cutters daily.

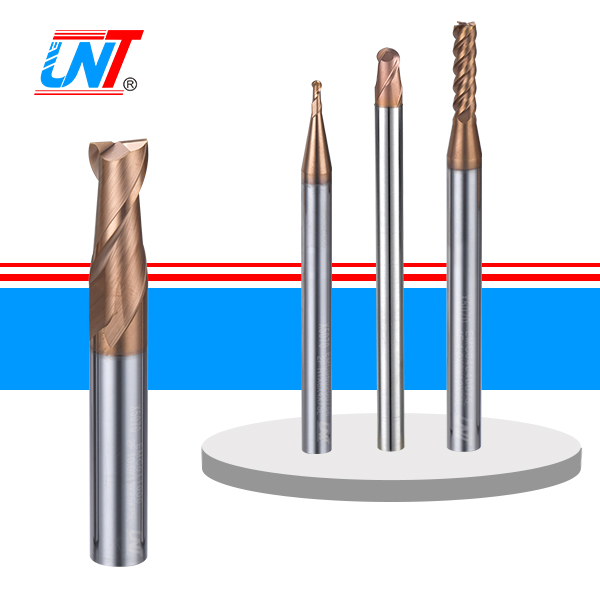

A Diverse Product Portfolio

UNT offers an extensive range of cutting tools, catering to multiple sectors. In the medical field, their dental and medical – grade cutting tools are a game – changer. Whether it’s working with materials like zirconium alloy, cobalt – chromium alloy, or titanium alloy, UNT’s milling tools provide cutting – edge quality and a high return on investment. These tools are designed with a wide selection of flutes and lengths, enabling them to be used in a variety of applications.

For the aerospace, 3C, automotive, nuclear power, and heavy machinery industries, UNT’s products such as carbide reamers, carbide taps, carbide drills, end mills, CNC tools, and molding cutters are highly sought after. Their single – flute end mills for acrylic, PVC, and MDF, diamond end mills for non – ferrous materials, micro – thread milling cutters, and carbide ball end mills for mold profile machining are just a few examples of the company’s diverse product line. Each product is made from prime – grade carbide and undergoes a special surface solution by Balzers, ensuring excellent tool life and edge treatment.

Quality Assurance and Certifications

Quality is at the heart of UNT’s operations. The company strictly controls product quality at every stage, from R & D and design to raw materials, production process control, product delivery, and product traceability. This commitment to quality has earned UNT the ISO9001 quality management system certification. Their products not only meet the requirements of customers but also adhere to international standards.

Global Reach and Reputation

UNT has established a strong global presence. It has long – term and stable business relationships with well – known OEM enterprises in the domestic Apple and Huawei supply chains. Additionally, the company provides long – term OEM services for customers in South Korea, Turkey, and exports its products to countries such as Sweden, Russia, Germany, Israel, and Vietnam. The positive reputation of UNT’s products in the international market is a testament to their quality and performance.

Customer – Centric Approach

UNT’s philosophy of “customer first” is evident in its operations. The company offers over 500,000 miniature specialty cutting tools that are fully stocked and ready to ship on the same day. It also provides a full – range of technical services related to mechanical processing, welcoming OEM and ODM partnerships and growing together with its customers.

In conclusion, Guangdong UNT Precision Cutting Tools Co., Ltd. continues to lead the way in the cutting tools industry, with its innovative products, commitment to quality, global reach, and customer – centric approach. As it looks towards the future, the company is set to keep innovating and creating maximum benefits for its customers across the globe.

[Here, you can insert relevant product images. For example, an image of their dental milling tools with a close - up of the sharp edges, an image of a carbide drill in a machining setup, or a group photo of their various end mills neatly arranged. You can search for these images on platforms like Unsplash, Pexels, or Getty Images (if you have access) and choose high - quality ones that match the description of UNT's products.]

Post time: Mar-19-2025